2020 官網(wǎng)升級中!現(xiàn)在您訪問官網(wǎng)的瀏覽器設(shè)備分辨率寬度低于1280px

請使用高分辨率寬度訪問。

CMS1431 has excellent cladding performance, with a flat cladding layer, high hardness, good corrosion resistance, good processability, and a strong metallurgical bond between the coating and the substrate that is not easily peeled off. Hydraulic supports and other hydraulic supports that can be used in the coal mining industry for surface cladding, as well as laminar cooling rollers in the steel industry.

Laminar cooling is a critical process in the hot rolling production of steel plates or strips. During service, the working temperature of laminar cooling rollers can reach 400-600 ℃, exposed to hot air and cooling water, and in direct contact with high-temperature steel plates. Therefore, the surface of the cooling roller must be resistant to corrosion, thermal fatigue, and wear. Under these service conditions, traditional flame spray welding coatings are prone to coating peeling problems. Laser cladding CMS1431 can achieve a very strong metallurgical bond between the coating and the substrate, thereby preventing coating delamination. In addition, laser cladding CMS1431 can also minimize sand holes in the coating to the greatest extent possible. For traditional flame spraying technology, sandblasting, preheating, flame spraying welding, remelting, and insulation are all essential steps. Compared to this, laser cladding of CMS1431 coating only requires one step of cladding. This not only improves efficiency, but also significantly reduces production costs. Shortening the production process and avoiding interruptions can significantly improve the quality of coatings and enhance the consistency of coating performance.CMS1431 laser cladding coatings have the following advantages:

1. Efficient, automated, and environmentally friendly coating process with high coating quality and good consistency

2. Excellent cladding performance, smooth cladding layer, high hardness, high corrosion resistance, and good processability

3. The strong metallurgical bond between the coating and the substrate is not easily peeled off

4. Compared to traditional flame spraying, the total cost is lower

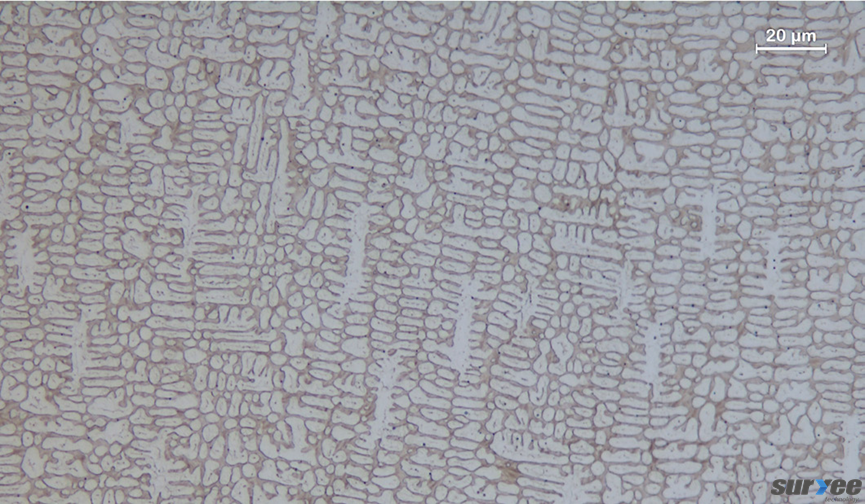

Coating microstructure